SiO2:≧ 95%

Bulk Density:≧2.0g/cm3

Apparent Porosity:≦17%

TCold Crushing Strength:≧60Mpa

Thermal expansion(1200℃):≦1.25-1.3%

Thermal Conductivity(1000℃):2.13W/m·k

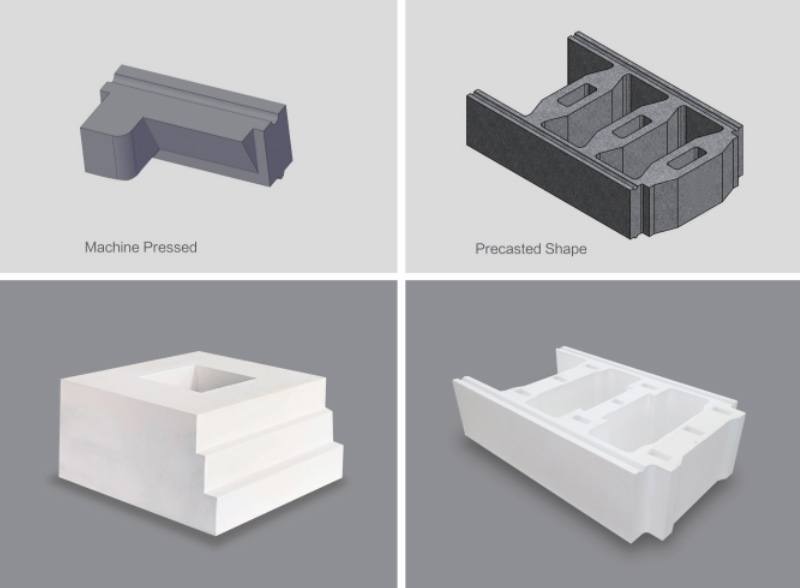

Introduction

State of the art technology,compact interface of welding,pre-sale trial in the pilot furnace accessible,portable projection.

Features

The new welding powder,provide welding test in the test furnace with welding machine beforesales,perfect welding with the original refractory structure in the furnace;

Best choice for partial repairs.

Pneumatic device,easy operation,without electricity required;

Portable,convenient for on-site operation;

Multiple explosion proof elements which ensure the safety.

Application

Coke Oven Hot Repair, Partial Repair of Coke Oven Walls

Glass Furnace Hot Repair

specification

| Properties | Unit | W8 | W98 | |

| Chemical Composition | SiO2 | % | ≥95 | ≥98 |

| Al2O3 | % | - | - | |

| Fe2O3 | % | - | - | |

| CaO | % | - | - | |

| Bulk Density | g/cm³ | ≥2.0 | ≥2.0 | |

| Porosity | % | ≤17 | ≤17 | |

| Cold Crushing Strength | Mpa | ≥60 | ≥60 | |

| Thermal expansion | 1200℃ | % | ≤1.25-1.3 | ≤1.25-1.3 |

| Thermal Conductivity | 1000℃ | W/m·k | 2.13 | 2.13 |

Online consultation

Thank you for your inquiry! A dedicated representative will contact you shortly to discuss your product quotation in detail and provide tailored solutions.