MERC have been devoted to offer refractory solution for coke oven hot repairs.The self-developed fused silica brick shows excellent performance with testimony by dozens of third party authority,institute,laboratory across the world.90% of them are for export to Japan,United States,Germany,France,Italy,Finland,South Africa,Turkey,Brazil,etc.Our company and bricks have gained a good reputation during the long-term cooperation with our partners home and abroad.

Excellent thermal shock resistance; nearly zero thermal expansion;

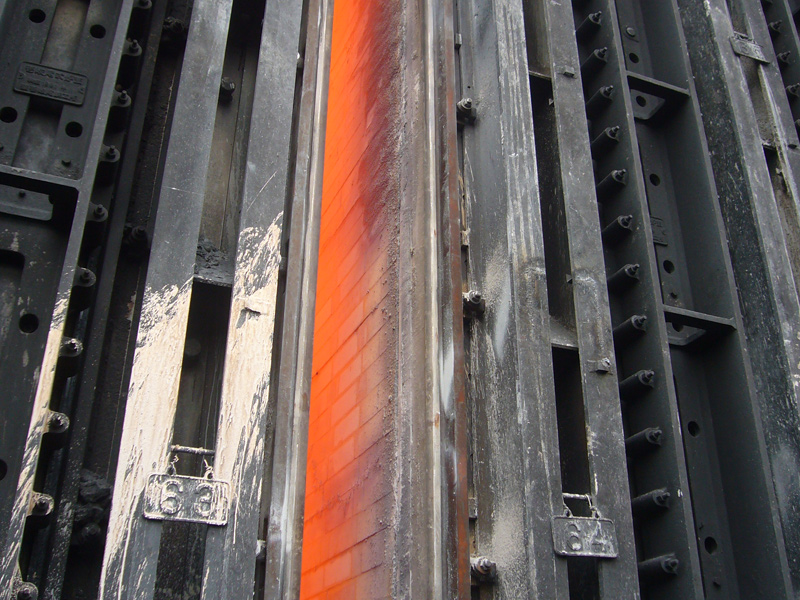

Applied for hot repair of coke oven walls and soles;it could also be adopted for modular repairs of aged coke oven which is seriously damaged;

No long term drying oven required, no preheating required,quick repair and more efficient;

High hot bending strength and hot crushing strength, longer service life.

Coke Oven Hot Repair;

Glass Furnace Hot Repair

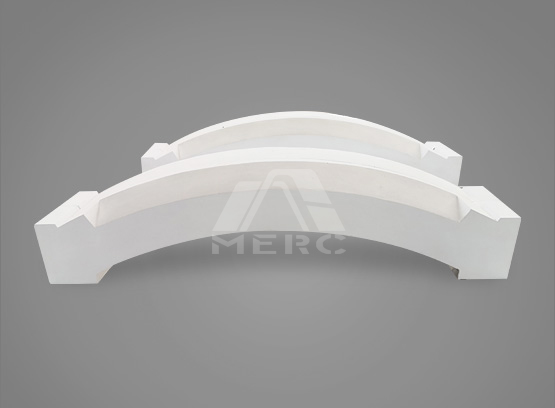

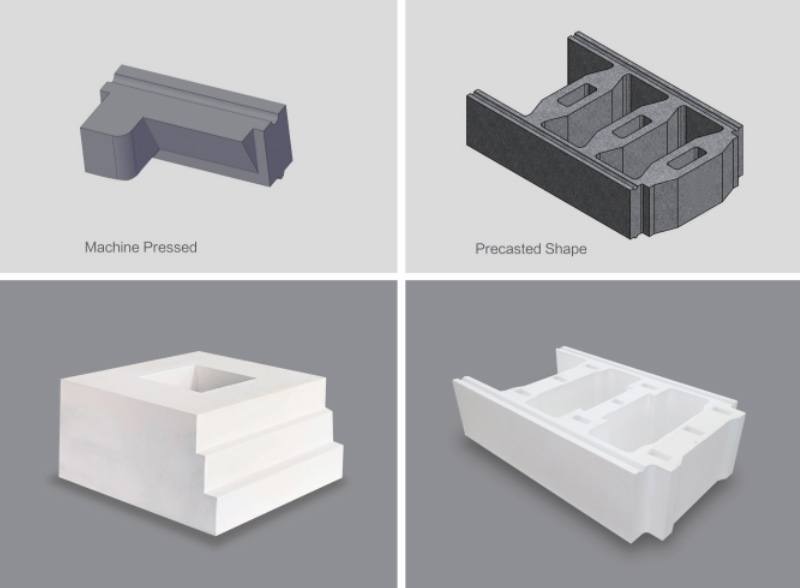

Shapes:

capable of all kinds of shapes including nozzles,super complicated shapes for corbel,regenerator,etc,the weight of a single brick ranges from 1kg to nearly 2tons.

Offer machining,drilling,pre-assembly service by clients’ request

| Properties | Unit | Value | |

| Chemical Composition | SiO2 | % | ≥99.0 |

| Fe2O3 | % | ≤0.3 | |

| CaO | % | ≤0.1 | |

| Alkalis | % | - | |

| Bulk Density | g/cm³ | ≥1.85 | |

| Apparent Porosity | % | ≤18 | |

| Cold Crushing Strength | Mpa | ≥40 | |

| Thermal Expansion | 1000℃ | % | ≤0.2 |

| Refractoriness Under Load | T0.6 | ℃ | ≥1680 |

| Thermal Shock Resistance | 1100℃ | cycles | >30 |

Online consultation

Thank you for your inquiry! A dedicated representative will contact you shortly to discuss your product quotation in detail and provide tailored solutions.