Excellent thermal shock resistance; nearly zero thermal expansion;

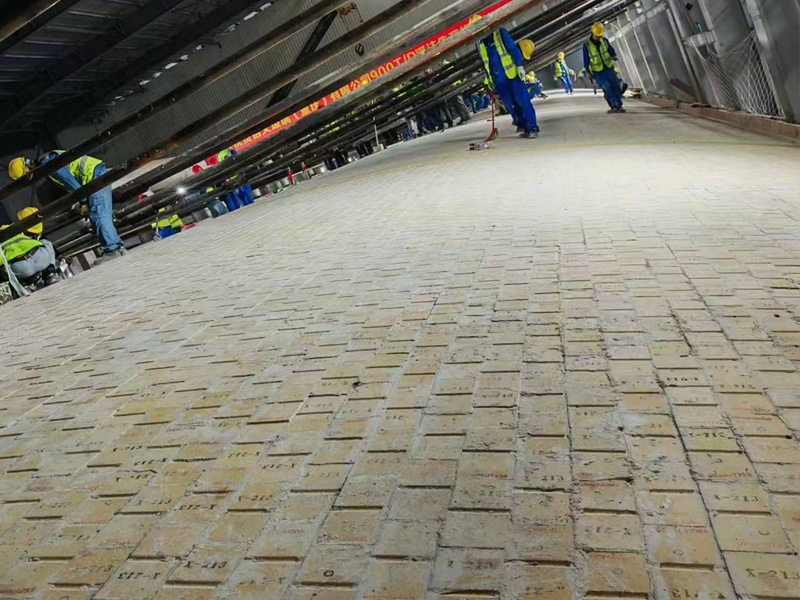

Fused silica brick ZES-99 can be directly installed in the glass furnace at high temperature without stopping the kiln;

Hot repairs for the crown of glass furnace, quick repair and safer suspended repair;

High hot bending strength and hot crushing strength, longer service life;

After being repaired, the kiln can be heated up quickly without preheating, which greatly shortens the construction period ;

Fused silica brick displays quite stable performance under thermal condition, meanwhile,it won't stain the glass fluid and no erosion and spaling occured, which proves it as rather reliable material for glass furnace hot repair.

| Properties | Unit | Value Machine Pressed | |

| Chemical Composition | SiO2 | % | ≥99.0 |

| Fe2O3 | % | ≤0.3 | |

| CaO | % | ≤0.1 | |

| Alkalis | % | - | |

| Bulk Density | g/cm³ | ≥1.85 | |

| Apparent Porosity | % | ≤18 | |

| Cold Crushing Strength | Mpa | ≥40 | |

| Thermal Expansion | 1000℃ | % | ≤0.2 |

| Refractoriness Under Load | T0.6 | ℃ | ≥1680 |

| Thermal Shock Resistance | 1100℃ | cycles | >30 |

Online consultation

Thank you for your inquiry! A dedicated representative will contact you shortly to discuss your product quotation in detail and provide tailored solutions.