SiO2:≧ 96.6%

Fe2O3:≦2%

CaO:≦1%

Bulk Density:≧1.9g/cm3

Apparent Porosity:≦18%

Introduction

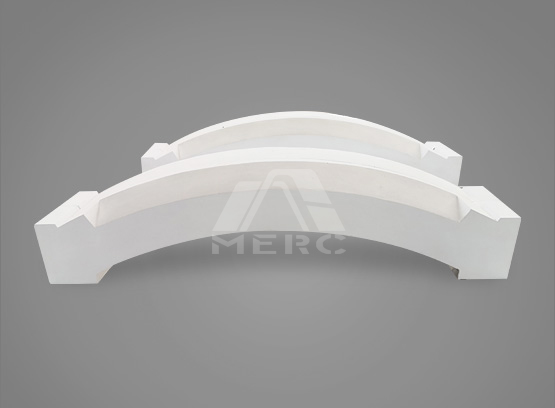

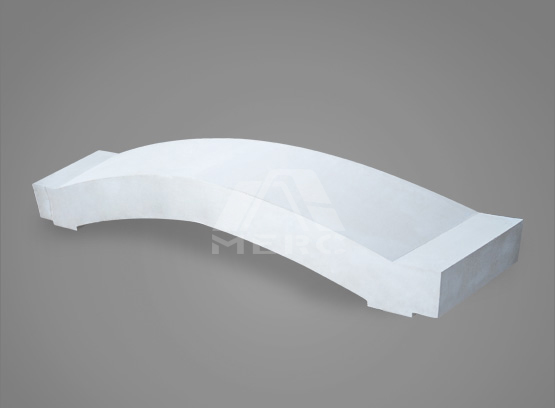

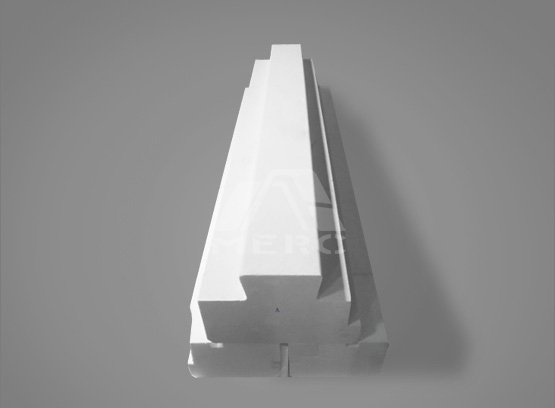

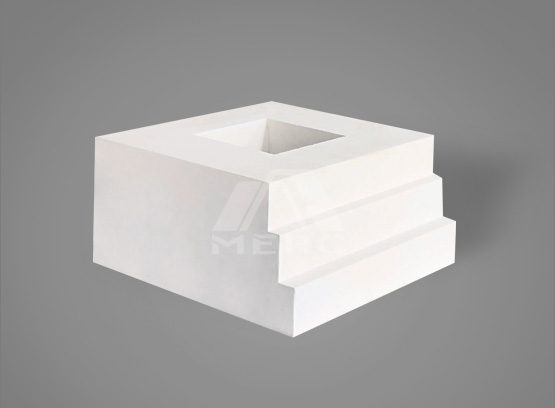

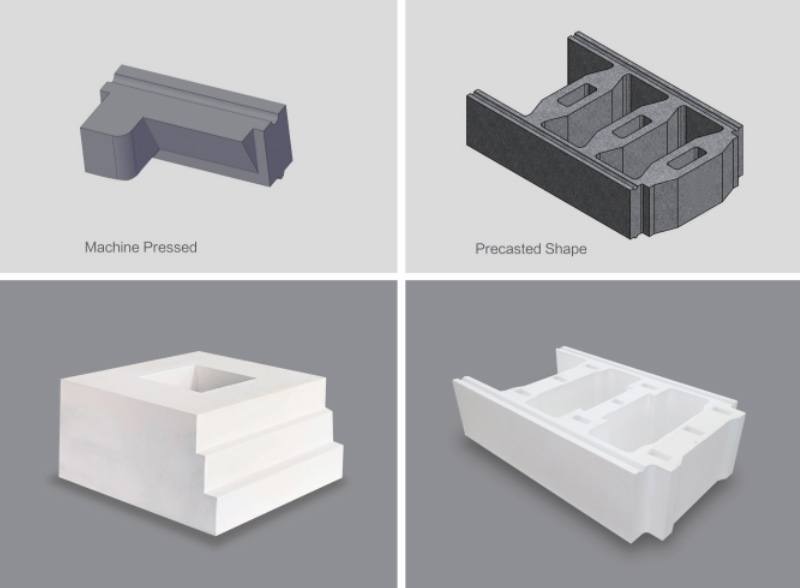

Fused silica modular block is first developed and introduced to solve the limit of dimension and shape for traditional fused silica.

By the applying the modules,installation could be made much faster with less manpower and less downtime which brings much benefit for users.

Features

Si02>97%, good alkali resistance;

Less joints, easy installation;

Good thermal shock resistance, can be directly used at high temperature without cracks;

Good high temperature strength,good erosion resistance.

Application

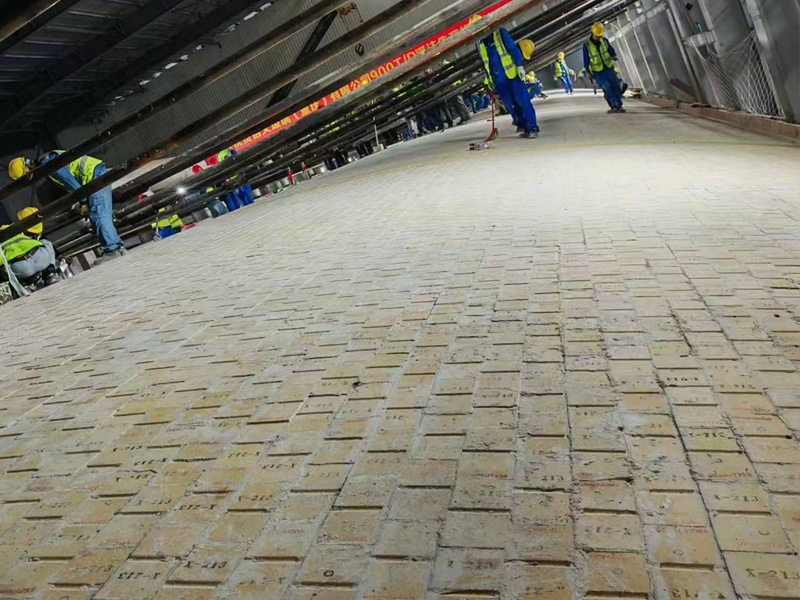

Coke Oven Hot Repair

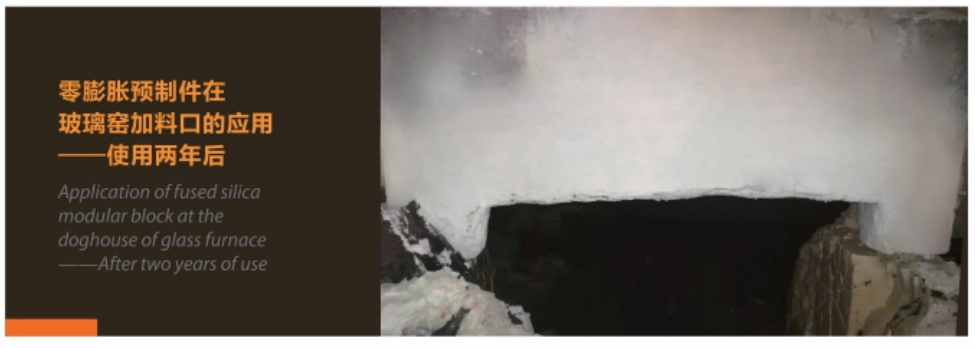

Glass Furnace Damper,Tweel,Doghouse Arch,Canal

specification

| Properties | Unit | CAST-99G Precast |

|

| Chemical Composition | SiO2 | % | ≥97.0 |

| Al2O3 | % | - | |

| Fe2O3 | % | ≤0.2 | |

| Bulk Density | g/cm³ | ≥1.93 | |

| Porosity | % | ≤16 | |

| Cold Crushing Strength | Mpa | ≥45 | |

| Thermal expansion | 1000℃ | % | ≤0.2 |

| Thermal Shock Resistance | 1100℃ with water | cycles | ≥30 |

| Traditional refractory products used for doghouse of glass furnace | Fused silica refractory products used for doghouse of glass furnace |

| Easy to press molding | High purity:SiO2 content >97.5% |

| Small unit weight,easy for masonry | Good thermal shock resistance:1100℃ water cooling >30 cycles |

| Strong arch structure | Low thermal expansion:thermal expansion rate <0.2% |

| Alkaline erosion in mortar joints | Capable of super large,complicate shapes |

| Difficult to maintain under hot condition | repair,easy installation |

| Difficult to repair and replace | Longer service life |

Online consultation

Thank you for your inquiry! A dedicated representative will contact you shortly to discuss your product quotation in detail and provide tailored solutions.