SiO2:≧ 96%(BG-96A) / 96%(BG-96B) / 95%(BG-95)

Fe2O3:≤ 0.6%(BG-96A) / 0.8%(BG-96B) / 1.0%(BG-95)

Apparent Porosity:≤ 21%(BG-96A) / 22%(BG-96B) / 22%(BG-95)

True Specific Gravity:≧2.34g/cm3(BG-96A) / 2.34g/cm3(BG-96B) / 2.34g/cm3(BG-95)

TCold Crushing Strength:≧40Mpa (BG-96A) / 35Mpa(BG-96B) / 30Mpa(BG-95)

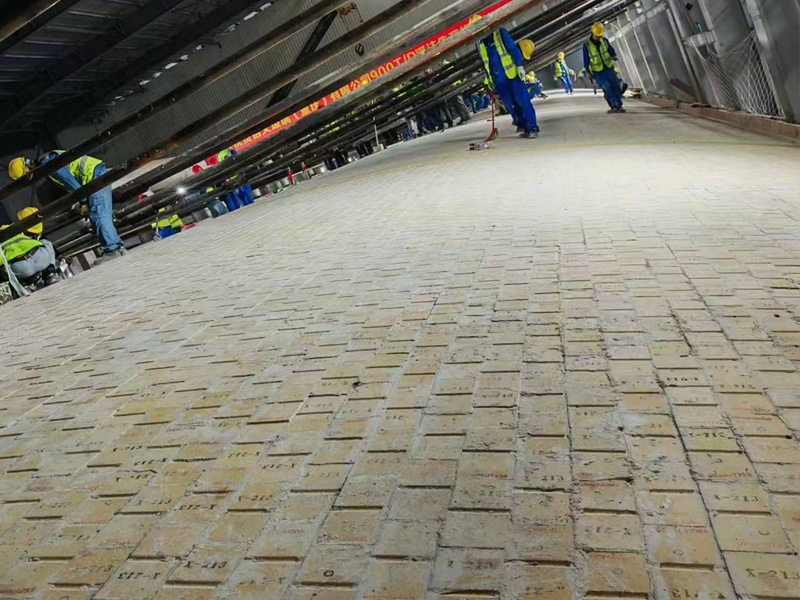

Introduction

With a skilled and experienced technical team which focused on silica refractories development and production for 30+ years,MERC guarantee to offer extraordinary silica bricks.

Features

High purity raw material, low fluxing agents Al203+2(K20+Na20)<0.5%;

residual quartz less than 1%, accurate dimension, thickness tolerance ±0.5mm.

Application

Glass Furnace Construction Projects

specification

| Properties | Unit | Value | |||

| BG-96A | BG-96B | BG-95 | |||

| Chemical Composition | SiO2 | % | ≥96.0 | ≥96.0 | ≥95.0 |

| Fe2O3 | % | ≤0.6 | ≤0.8 | ≤1.0 | |

| Al2O3+2(K2O+Na2O) | % | ≤0.5 | ≤0.7 | - | |

| True Specific Gravity | g/cm³ | ≤2.34 | ≤2.34 | ≤2.34 | |

| Apparent Porosity | % | ≤21 | ≤22 | ≤22 | |

| Cold Crushing Strength | Mpa | ≥40 | ≥35 | ≥30 | |

| Refractoriness Under Load | T0.5 | ℃ | ≥1680 | ≥1680 | ≥1670 |

| Permanent Linear Change | 1450℃×2h | % | 0-0.2 | 0-0.2 | 0-0.2 |

| Residual Quartz | % | ≤1 | ≤1 | ≤1 | |

| Dimension Tolerance | Wedge brick | ≤100mm | ±0.5mm |

| Size | ≤100mm | ±0.5mm | |

| Size | 100mm~≤350mm | ±1mm | |

| Size | >350mm | ±1.5mm | |

| Warpage | Brick length or crown height | ≤525mm | ≤1mm |

| Brick length or crown height | >525mm | ≤1.5mm | |

| (a+b+c) Corner Damage | Hot surface | -- | ≤15mm, (Two damages accept) |

| Normal surface | -- | ≤25mm, (Two damages accept) |

|

| (e+F+g) Edge Damage | Hot surface | -- | ≤15mm, (One damages accept) |

| Normal surface | -- | ≤30mm, (Two damages accept) |

|

| Crater Diameter | Hot surface | -- | Not Allowed |

| Normal surface | -- | ≤4mm | |

| Length of Crack | Width≤0.1mm | -- | Allowed |

| Width 0.11~0.25mm | Hot surface | ≤20mm | |

| Normal surface | ≤40mm | ||

| Width 0.26~0.5mm | Hot surface | Not Allowed | |

| Normal surface | ≤20mm | ||

| Width>0.5mm | -- | Not Allowed | |

| Lamination | -- | -- | Not Allowed |

Online consultation

Thank you for your inquiry! A dedicated representative will contact you shortly to discuss your product quotation in detail and provide tailored solutions.