SiO2:≧ 95%

Fe2O3:≦1%

Apparent Porosity:≦22%

A12O3:≦1%

True Density:≦2.33g/cm3

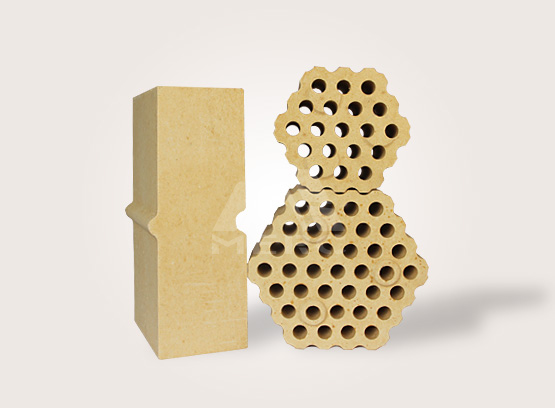

Introduction

Silica brick is mainly used for hot-blast stove, tunnel kiln, coke oven, glass kiln, acidic furnace non-ferrous metal smelting and some other thermo technical equipment in good furnace building materials.

Features

High purity, good thermal conductivity;

High refractoriness under load and high tridymite content;

Low true density, low expansion, low creep and low residual quartz content;

Good dimension and appearance.

Application

Widely used in hot blast stoves.

Used in high temperature sections of the checker chamber in hot blast stoves.

Used as low-cost alternative to andalusite and mullite checker bricks in hot blast stoves.

High refractoriness, average thermal shock resistance makes it suitable in consistent temperature environment.

specification

| Properties | Wall bricks Dome Bricks |

Checker Brick |

| SiO2% | ≥95 | ≥95 |

| A12O3% | ≤1.0 | ≤1.0 |

| Fe2O3% | ≤1.0 | ≤1.0 |

| Apparent Porosity % | ≤22 | ≤24 |

| True Density g/cm³ | ≤2.33 | ≤2.33 |

| Cold Crushing Strength MPa | ≥40 | ≥35 |

| Refractoriness Under Load (0.2MPa) ℃ | ≥1650 | ≥1650 |

| Residual Quartz % | ≤1.0 | ≤1.0 |

| Creep Rate 0.2MPa (1550℃*50h) % | ≤0.6 | ≤0.6 |

| Permanent Linear Change( 1450℃*2h) % | ≤0.2 | ≤0.2 |

| Thermal Expansion Coefficient(1000℃) % | ≤1.26 | ≤1.26 |

Online consultation

Thank you for your inquiry! A dedicated representative will contact you shortly to discuss your product quotation in detail and provide tailored solutions.